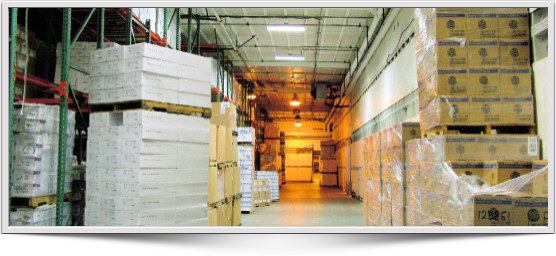

Lighting for Cold Storage and Food Production/Distribution

Freezer and Refrigeration lighting

ALED’sLED, Induction and T5 Fluorescent cold storage lighting system wills deliver substantial energy savings while improving on safety and productivity due to better light qualities. If your facility currently uses 250-watt, 400-watt, 1000-watt metal halides or high pressure sodium (HID) fixtures Switching to our fixtures will typically result in a 50% energy reduction in freezer applications and potentially higher savings in reefers, production, and distribution areas by implementing the use of occupancy sensors built into the fixtures.

ALED’sLED, Induction and T5 Fluorescent cold storage lighting system wills deliver substantial energy savings while improving on safety and productivity due to better light qualities. If your facility currently uses 250-watt, 400-watt, 1000-watt metal halides or high pressure sodium (HID) fixtures Switching to our fixtures will typically result in a 50% energy reduction in freezer applications and potentially higher savings in reefers, production, and distribution areas by implementing the use of occupancy sensors built into the fixtures.

In addition to the wattage reduction, all three of our cold environment fixtures introduce far less heat into your cold storage environment. HID fixtures operate very hot. Our T-5 fluorescent, Induction and LED fixtures run up to 70% cooler than HID fixtures, which can result in an additional 12%-19% energy savings.

Maintenance in freezer environments is considerably more expensive than a non refrigerated environment, a rule of thumb is the cost is typically double or more, compared to non refrigerated facilities. ALED fixtures were design to lower the maintenance cost with lamp life ratings of 100,000 hours for the induction, 50,000 hours on the LED and 35,000 – 60,000 hours for the fluorescent.

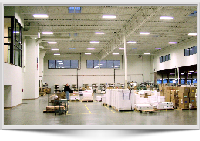

Food Grade Production and Distribution Lighting

Lighting quality in a food production and/or a processing facility is very critical and often substandard for the work environment campared to the lighting qualities of new technology lamps. These types of facilities typically have several different types of tasks being performed, and many require different lighting technologies and levels of light to allow the processor to function efficiently. Proper lighting will also enhance productivity and provide a higher level of quality control. In some facilities, this alone can outweigh the dramatic energy savings our lighting systems achieve

Lighting quality in a food production and/or a processing facility is very critical and often substandard for the work environment campared to the lighting qualities of new technology lamps. These types of facilities typically have several different types of tasks being performed, and many require different lighting technologies and levels of light to allow the processor to function efficiently. Proper lighting will also enhance productivity and provide a higher level of quality control. In some facilities, this alone can outweigh the dramatic energy savings our lighting systems achieve

Maintenance of any piece of equipment be it machinery or simple lamp replacecment in a food processing environment can be cumbersome and costly often requiring shut down of the area and then sanitation. If your facility currently has metal halides their lamp life is only rated at 10,000-20,000 hours. Our Induction Lighting systems have a manufactures lamp life rating of 100,000,000 hours, LED fixtures at 50,000 hours, and the T5 fluorescent at 35,000-60,000 hour. This results in your maintenance cost being dramatically reduced and fewer interruptions to your production schedule.

Lamp Life Chart

The chart below represents the manufactures rated lamp life of the various lamp technologies. Note: manufacture rated lamp life assumes that 50% of the lamps will have failed at the rated life. With that said best practice is to assume actual lamp life is roughly 75% of the rated life. The below estimates are based on 2-shifts 5 days per week 52-weeks.

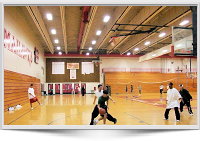

Sports Lighting

Sports Lighting